navigation

navigation

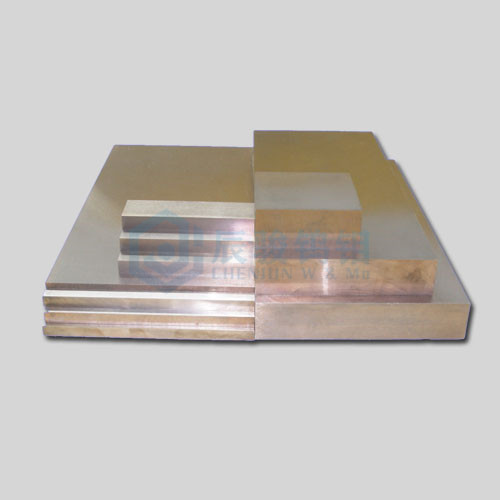

Product details

Tungsten-copper alloy, also known as cu-tungsten alloy, is composed of copper and refractory tungsten. The copper content of common alloys is 10% ~ 50%.Tungsten-copper alloy has good conductivity, high temperature strength and certain plasticity.At very high temperatures, such as above 3000°C, the copper in the alloy is liquefied and evaporated, absorbing a large amount of heat and reducing the surface temperature of the material, so this kind of material is also known as metal sweating material.

Standard: GB/T 8320-2017, ASTM B 702

Size: customized

Product characteristics:

-- High strength, high density, high temperature resistance

-- Arc ablative resistance and good electric conductivity

-- Good machining performance

Tungsten-copper alloy parameters:

Class | Chemical composition(wt%) | Density | Hardness | Resistivity | Electric conductivity | Bending strength | ||

Cu | Sum of impurities ≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | IACS/% % ≥ | MPa ≥ | |

W50/Cu50 | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | -- |

W55/Cu45 | 45±2.0 | 0.5 | Balance | 12.3 | 125 | 3.5 | 49 | -- |

W60/Cu40 | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | -- |

W65/Cu35 | 35±2.0 | 0.5 | Balance | 13.3 | 155 | 3.9 | 44 | -- |

W70/Cu30 | 30±2.0 | 0.5 | Balance | 13.8 | 175 | 4.1 | 42 | 790 |

W75/Cu25 | 25±2.0 | 0.5 | Balance | 14.5 | 195 | 4.5 | 38 | 885 |

W80/Cu20 | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5 | 34 | 980 |

W85/Cu15 | 15±2.0 | 0.5 | Balance | 15.9 | 240 | 5.7 | 30 | 1080 |

W90/Cu10 | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

Applications:

-- Used as arc contact and vacuum contact of high voltage switch or circuit breaker

-- Used as high temperature resistant materials

-- Used as electrodes for EDM

-- Used in Microelectronic materials industry

-- Used as electronic packaging materials and heat sink materials