navigation

navigation

Product details

TZM alloys are molybdenum alloys containing 0.4~0.6%(WT) of titanium, 0.08~0.12%(WT) of zirconium, and 0.02 ~ 0.03% (WT) of carbon, also known as molybdenum titanium-zirconium alloys.

Process: Powder metallurgy

Standard:ASTM B386-364 , ASTM B387-364

Material features:

--High melting point, high strength, high elastic modulus

--Small linear expansion coefficient

--Low vapor pressure

--Good electrical and thermal conductivity

--Corrosion resistance

--Excellent mechanical properties at high temperature

Compared with pure molybdenum, TZM alloys have the following advantages:

-- Better strength at high temperatures and higher recrystallization temperatures

-- Better plasticity at room temperature

-- Better welding performance

Applications:

--Used as high-temperature components, such as rocket nozzle throat lining, flight rudder splint, etc

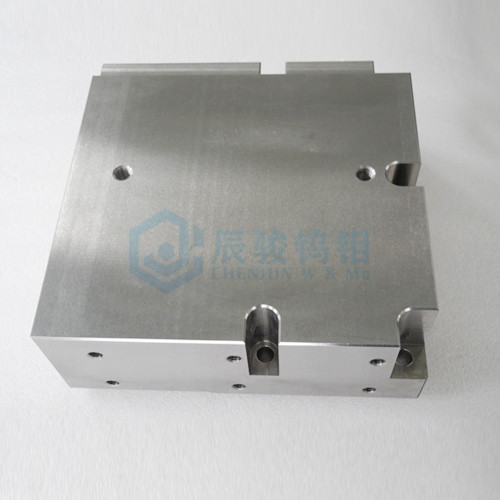

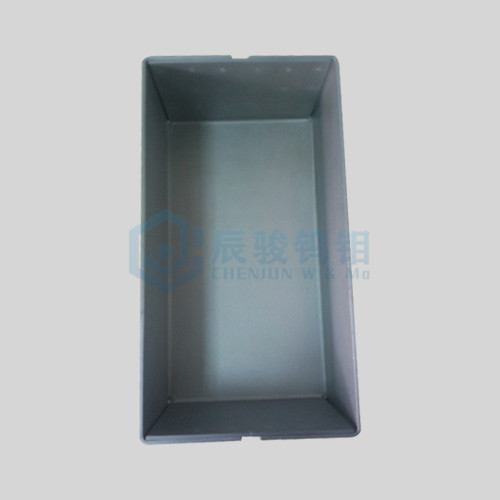

-- For producing metal hot-working molds, such as die-casting, extrusion dies, etc

-- Used as heating element and heat insulation screen in vacuum furnace

Chenjun can produce and supply the following high-quality TZM alloy products:

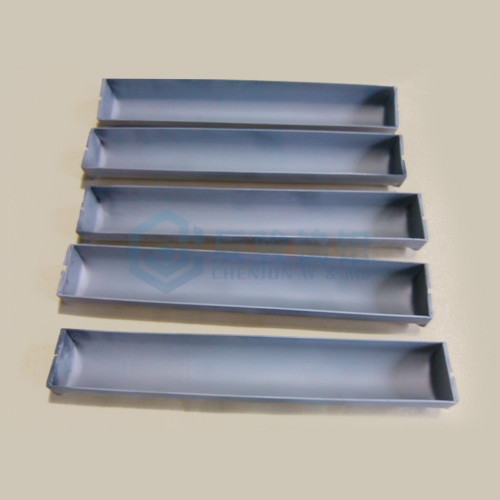

--TZM plate/board/sheet/foil/strip

--TZM rod/bar/wire

--TZM target/tube/ring

--TZM screen/heat shield/reflection shield

--TZM bolt/screw/nut/washer

--TZM customized parts