navigation

navigation

Products details

Mo crucible

Material:Mo1

Purity:≥99.95%

Types: sintered, forged, welded

Size: Dia10-500mm, customized

Conventional density:9.8g/cm3~10.0 g/cm3

High density:≥10.1g/cm3

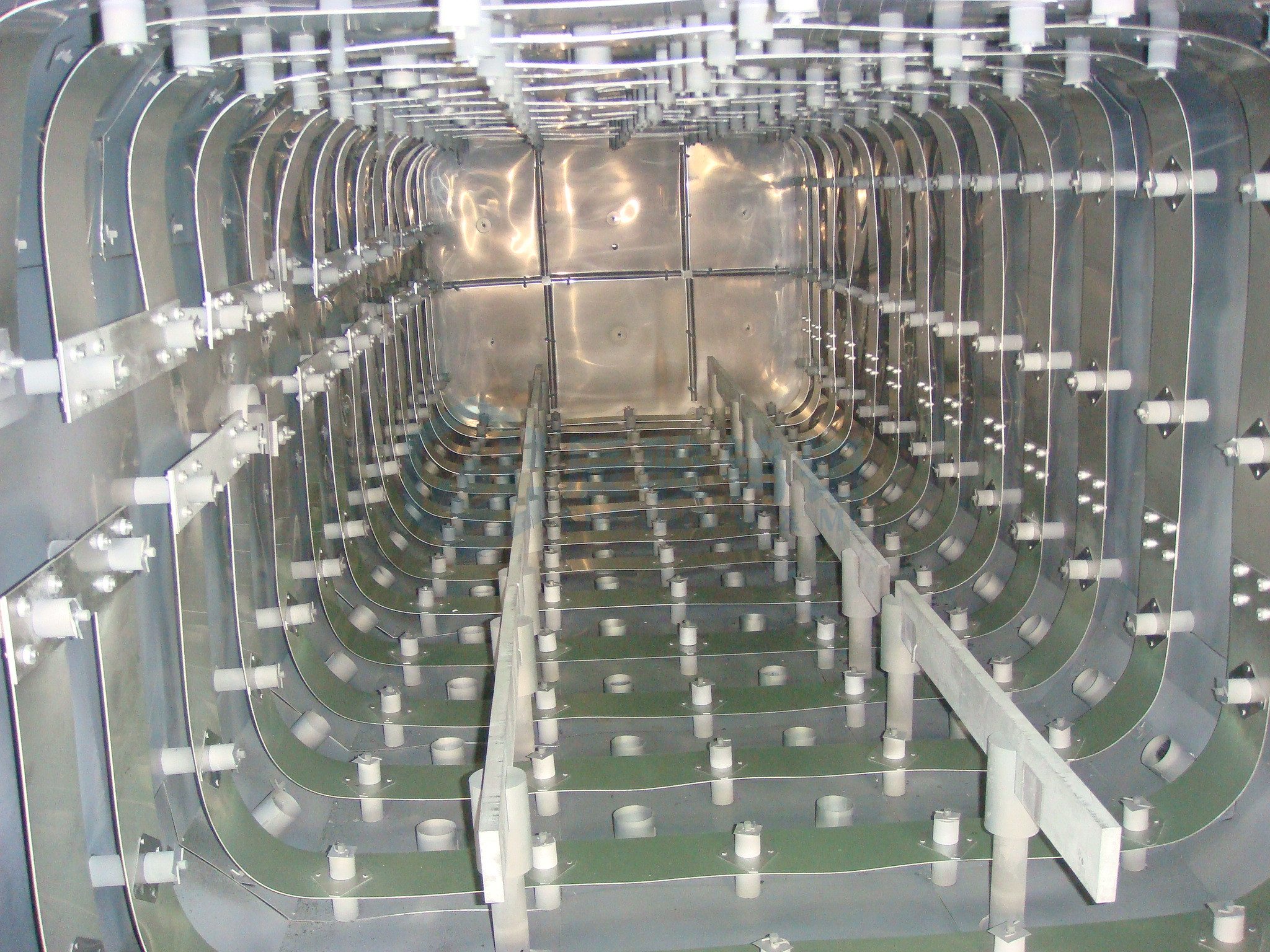

Other parts of hot zone

Material: W1, Mo1

Product name: Crucible cover, Tube, Supporting rod, Disk, Bottom plate, Herater, Screen, Seed holder, Shield, Fastener, Cap, Sector, Tray , etc.

Dimension: Customized

Product characteristics:

-- High temperature strength, high density and even internal organization.

-- Tungsten crucible can be used in a vacuum or inert gas under 2600 degrees centigrade.

Specifications:

Name | Material | Diameter (mm) | Height (mm) | Wall thickness (mm) | |

Forged crucible | Mo1,MoLa,WMo | Ф10-80 | 15-150 | 2~10 | |

Sintered crucible | Mo1,MoLa,WMo | 80-750 | 50-800 | ≥8 | |

Screen/shield | Mo1,MoLa,W | Customized | |||

Side screen | Mo1,MoLa,W | Customized | |||

Support rod | W | Customized | |||

Bottom plate | W | Customized | |||

Crucible cover | W | Customized | |||

Heater | W,Cu | Customized | |||

Seed holder | Mo,MoLa | Customized | |||

Heating belt | Mo1,MoLa | Customized | |||

Reflective screen | Mo1,MoLa | Customized | |||

Custom sizes available upon request. Your special requests are available.

Chemical composition:

Material | Content | Total impurity content | Individual element content |

W1 | ≥99.95% | ≤0.05% | ≤0.01% |

Mo1 | ≥99.95% | ≤0.05% | ≤0.01% |

Production technology for different molybdenum crucibles:

Forging Molybdenum crucible:

Powder--Pressing--Sintering--Forging--Lathe processing--Surface cleaning--Quality

testing -Packing--Shipment

Sintered molybdenum crucible:

Powder--Pressing--Sintering--Lathe Processing--Surface cleaning-Quality testing--

Packing-shipment

Welded tungsten crucible:

Powder--Pressing--Sintering--Rolling--Welding--Surface cleaning-Quality testing--

Packing-shipment

Crucible can be processed according to drawing, and solutions can be provided according to use requirements.

Applications:

-- Used in rare earth smelting industry

-- Used in sapphire crystal furnace

-- Used in quartz and glass smelting industry

-- Used in vacuum coating industry

-- Used in monocrystalline silicon furnace