navigation

Products details

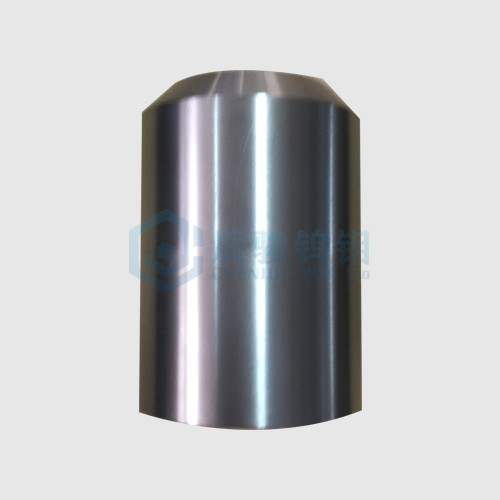

Name: Cr target/Chromium target

Material: Cr

Purity: 99.5%,99.7%,99.8%,99.9%,99.95%

Type: Plane target, Rotary target

Shape: Tube, Square, Round, Oblong

Density: >7.17g/cm3

Surface roughness: Ra≤0.4μm

Size: Customized

Product characteristics:

-- High density

-- High purity

-- Fine grain

Applications:

-- Used in thin-film solar industry

-- Used in semiconductor industry

-- Used in optical coating industry

-- Used in surface decoration and tool coating industry

Process flow:

Powder--pressing--sintering--hot isostatic pressing--deep processing--surface treatment-- finished products --inspection - packing

HIP Process

Hot isostatic pressing (HIP) is a kind of production technology integrating high temperature and high pressure. The heating temperature is usually 1000 ~2000°C, and the working pressure can reach 200MPa by using high pressure inert gas or nitrogen in a sealed container as the pressure transmission medium. Under the joint action of high temperature and high pressure, the workpiece is evenly pressed in all directions. Therefore, processed products have high density, good uniformity and excellent performance. At the same time, the technology has the characteristics of short production cycle, less working procedure, low energy consumption and low material loss.

Advantages of HIP technology in producing targets:

--Eliminating the porosity

--Improving mechanical properties,

--Extending the service life of the product

--Making grain structure Finer and more uniform

--Improving the surface quality of machining

Chenjun can produce and supply the following high quality target:

W target, Mo target, MoNb target, Nb target, Cr target, Ti target,Ta target